Electroerosive machining

Enquiry

Send us an enquiry for EDM

Pre-production work

To ensure maximum efficiency of pre-production stages of orders, the fully integrated CAMWorks CAM system is used, which offers a complete set of functions for EDM machining, including object recognition technology and automatic determination of machining technology.

Thanks to this technology, CAMWorks is a very powerful tool with which it is possible to achieve great savings in machining time.

Production process

The Mitsubishi MV2400S EDM machine is used for the production process, which is one of the most modern machines on the market. This machine achieves high dimensional accuracy, it is possible to machine very complex contours and shapes in very precise surface qualities, it also has a high variability of cut material heights.

The maximum dimensions of the workpiece are 1050x820x305 mm, the maximum weight is 1500 kg and a roughness of up to Ra 0.3 can be achieved.

Control process

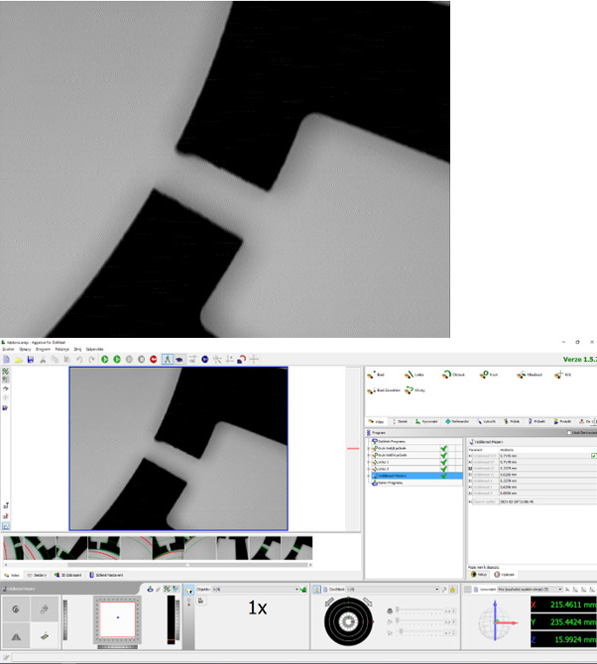

Regular control measurements are performed on a CNC measuring device of the DeMeet 404 brand, which enables measurements not only with the help of touch probes, but also with the help of interchangeable optical lenses.

In addition to the standard equipment, the measuring device is supplemented with a touch tray to enable full automation of measuring sequences of complicated geometries, including automated generation of survey protocols from each measuring sequence.